Механики XXI веку. № 15 2016 г.

442

tion of these values and parameters impact design solutions and allows improving the efficiency of earthmoving

equipment, developing the wet ground in freezing conditions.

Introduction.

The increase in adhesion and friction is the main reason of the earth-moving machines

efficiency degradation when exploiting damp coherent soils under subzero temperatures. The adhesive phe-

nomena cause drastic increase of friction forces, they equal 30-60% of traction [1-3].

The existing methods to decrease friction and sticking can be divided into four groups (methods).

The first method includes creation of an intermediate layer in the contact boundary, this layer can serve as

the filter for the phases molecular interaction and has to possess adhesive interaction [4-7]. The second group

includes the methods promoting adhesive bonds decreasing due to external action [8]. The third method is

based on structurally technological and mechanical practice [9]. The fourth group is the combination of two

or more methods to decrease adhesion [10, 11]. Widely applied and perspective preventive method of adhe-

sion control is to create an intermediate layer in the contact boundary of "soil -operational surface system".

This layer serves as a screen for intermolecular interaction forces, i.e. it provides free relative displacement

of phase surfaces and may be liquid, solid or gaseous. The layer thickness must be designed to get anti-

adhesive properties.

Main part.

Let’s consider the applying of anti-icing liquids (AIL) as the liquid intermediate layer.

AIL "MAXFLIGHT 04" and "OCTAFLO EG" are anti-icing liquids based on propylene glycol [12] and are

intended for land anti-icing treatment of aircrafts. They possess high anti-icing characteristics when being

used heated up +70 ºС without any operational limits. The time of the AIL keeping on the wing (Holdver-

time) varies from 3 minutes to 12 hours.

There were made the experiments on shift resistance of the damp coherent soil relatively metal sur-

face by applying AIL "MAXFLIGHT 04" and "OCTAFLO EG" at the air temperatures from-35 to +5 ºС.

The experiments were made on the special shift stand [13-17].

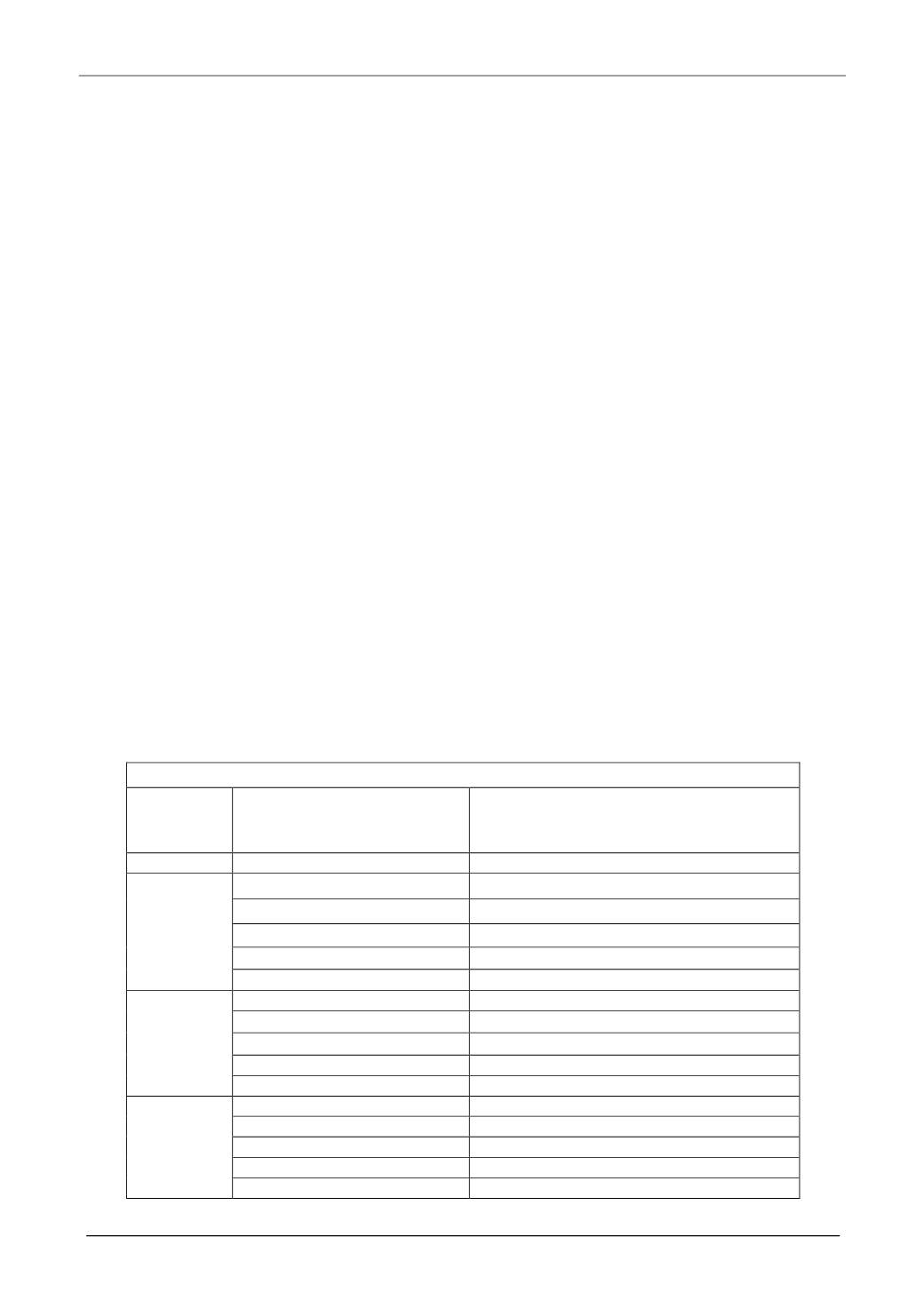

To make the experiments the loam soil of 7.5-17.5% moisture content was used, to say, the time of

the soil-metal surfaces contact was 3 - 7 minutes that corresponds to the operational parameters of earth-

moving machinery. The plan and results of the experiments are shown in the table 1.

Mathematical processing of the obtained results data was made by using the MODEL program in-

tended for multiple-factor dependences calculation with the method of the smallest squares. The experiments

data processing resulted in getting the regression equations without action of a grease material and by using

AIL "MAXFLIGHT 04" and "OCTAFLO EG".

Table 1

Plan and results of the experiment

The plan of experiment in natural values

Enviroment

temperature

T,

о

С

Soil moisture content W, %

Contact time of soil-metal system t, min.

1

2

3

7.5

3

7.5

7

12,5

5

17,5

3

-35

17,5

7

7,5

5

12,5

3

12,5

5

12,5

7

-15

17,5

5

7.5

3

7.5

7

12,5

5

17,5

3

+5

17,5

7